Tung Oil vs Linseed Oil

TUNG OIL - The Most Waterproof Natural Finish

Brief Overview: Tung oil is derived from the seeds of tung trees, native to China and other parts of Asia. The oil is extracted with a heavy-duty pressing machine, the process is more commonly known as "cold pressed". Tung oil is known for its high content of polyunsaturated fatty acids, primarily alpha-eleostearic acid. This unique fatty acid polymerizes when exposed to air, forming a protective and durable finish on wood. Historically, it has been used for sealing ships, and finishing furniture, and wooden beams in homes.Drying Time (dries slower): Pure Tung Oil will take longer to cure than Polymerized Linseed Oil since it's 100% pure and unprocessed by way of heat. It can take several days to feel dry to touch and up to a few weeks to fully cure and harden, depending on factors such as temperature and humidity. This slow drying time can be a disadvantage for projects that require a quick finish, however when it comes to natural alternatives for sealing wood surfaces, especially outdoors, Pure Tung Oil is unmatched.

Durability (more waterproof): Tung oil is highly renowned for its durability. It is exceptionally resistant to water, chemicals, and abrasion. This makes it an excellent choice for outdoor applications, such as outdoor furniture, grill accessories, wooden garden boxes, and other projects that will be exposed to outside elements. Tung oil can withstand the elements and maintain its protective qualities for extended periods. Of course tung oil is also suitable for high traffic indoor projects, such as dining tables and unfinished hardwood floors.

Application (easier to apply): In its raw form, its a heavy but smooth oil that can be easier to apply than Polymerized Linseed Oil. Generally application pads are recommended, but it can be applied with your hand.

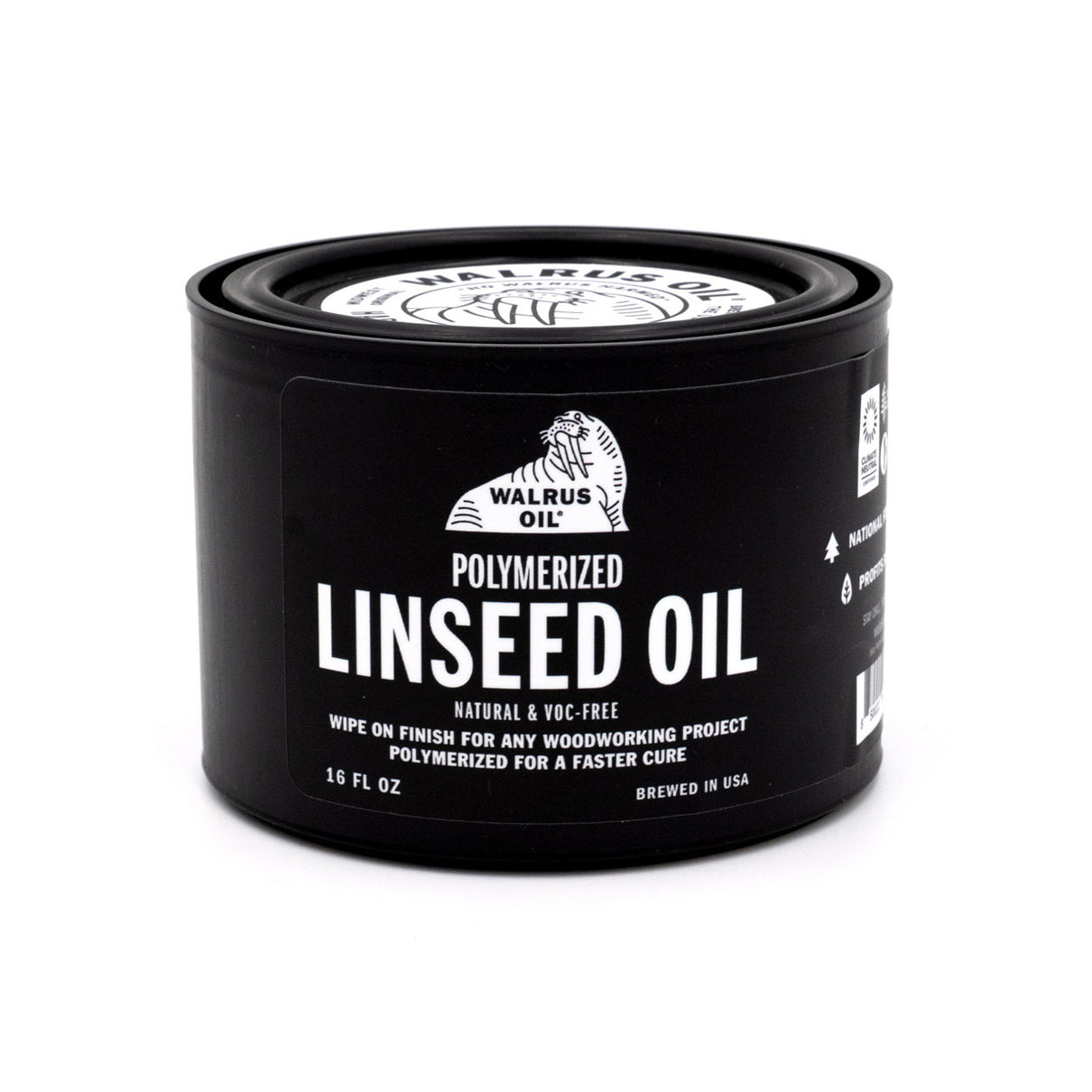

LINSEED OIL - The Fastest Curing Natural Finish

Brief Overview: Linseed Oil is extracted from the seeds of the flax plant. Flax has been cultivated for thousands of years and linseed oil has been used for various purposes, including wood finishes. Linseed oil contains a high percentage of linolenic acid and alpha-linolenic acid, which, like alpha-eleostearic acid in tung oil, polymerizes when it comes into contact with oxygen. This polymerization process is what causes the oil to harden and form a protective coating. Walrus Oil's Polymerized Linseed Oil has gone through a heating process to speed up the polymerization, so it will begin to cure even faster when applied to wood. While some companies use potentially harmful metals and dryers to polymerize their linseed oil, Walrus Oil does not and only processes our product through heat.Drying Time (dries faster): One of the most significant differences between tung oil and linseed oil is their drying time. Linseed oil, in contrast, dries relatively quickly, typically within 24 hours it's dry to touch. This faster drying time makes it a more suitable choice for projects where a speedy finish is desired. This also makes it easier to build coats of finish.

Durability (less waterproof): While linseed oil provides adequate protection for wood surfaces, it is generally not as resistant to moisture and UV exposure as tung oil. Linseed oil is better suited for indoor applications, such as furniture and cabinetry, where it can provide a protective finish without the need for extreme durability.

Application (harder to apply): In its raw form, due to it's pre-polymerization, its a very-thick oil and stickier than Pure Tung Oil. We recommend application pads or sandpaper when applying. Because of it's consistency, some may prefer to mix it with a natural solvent, although this is not required. It will require more buffing than Pure Tung Oil to apply and to remove any excess finish, though some may view this as a positive feature since more buffing contributes to more sheen.

Comments

WALRUS OIL:

To Mary: our Furniture Butter, which contains both Tung Oil and Linseed Oil has been used by many customers to seal milk painted surfaces.

Apr 17, 2024

Wayne Howell:

Thank you for the great article as I am undecided about which finish to apply to my Teak door. I do not like the fact that Teak oil will darken it further.

Apr 17, 2024

Mary :

Can these products be used on painted items.

Looking to water proof a painted window sill . Needs to hold up to potted plants.

Apr 17, 2024

WALRUS OIL:

To Gregory T. Ahlgren: Pure Tung Oil is going to offer better protection from UV, direct sunlight, and for outdoor projects.

Dec 19, 2023

gregory t ahlgren:

I plan on making a table that could get a small amount of sun. Which of these two would be the best to use? Alson which would be best for outdoors in the elements?

Dec 19, 2023

WALRUS OIL:

To Michael Myers: the primary difference between Cutting Board Oil and the products in this post (Tung Oil and Linseed), is Cutting Board Oil is non-polymerizing, meaning it doesn’t harden. The advantage of Cutting Board Oil is it holds up better to daily washing, and when re-applied for maintenance, you don’t have to wait for the product to completely cure before using the cutting board.

Tung Oil and Linseed Oil on the other hand needs to fully cure before coming into contact with water for best results, which can take weeks. This is why they’re not always recommended for cutting boards. These products are best designed for furniture, cabinets, etc. That being said, every product we make is food-contact safe, so if you prefer the look of Tung Oil or Linseed Oil, it’s safe to use on cutting boards too.

Dec 18, 2023

Michael Myers :

I have used your cutting board oil and wax on all of my boards, platters, and bowls. I have always had good results on my personal boards, and I have never had any issues from any boards I have sold

I am curious about that finishes described above, but I am wondering if they provide any advantage to the product I currently using. Tung Oil sounds promising for water protection especially on cutting boards. Linseed sounds less protective to wear.

So…I guess the question is if you were crafting a cutting board, platter, or bowl what finish would you use?

Thanks for all of the information, and for your wonderful products and support.

Dec 18, 2023

Kris:

I used tung oil on a coffee table. It took about a week to cure. I’ve since cut that table in half for two end tables. I’ve used your furniture butter ever since then. They are totally water proof!

Dec 18, 2023

Jon:

Great article. Thank you for sharing and clarification of the oils.

Dec 18, 2023

WALRUS OIL:

To M L Runge: once our finishes are fully cured, generally other oil-based finishes can be used over them. We do recommend testing in a small area beforehand to make sure you like the results.

To Jesse Glessner: every product we make contains only 100% food-contact safe ingredients. Both of these products can be used with cutting boards, wooden spoons, etc.

Dec 18, 2023

Leave a comment