Tung Oil vs Linseed Oil

TUNG OIL - The Most Waterproof Natural Finish

Brief Overview: Tung oil is derived from the seeds of tung trees, native to China and other parts of Asia. The oil is extracted with a heavy-duty pressing machine, the process is more commonly known as "cold pressed". Tung oil is known for its high content of polyunsaturated fatty acids, primarily alpha-eleostearic acid. This unique fatty acid polymerizes when exposed to air, forming a protective and durable finish on wood. Historically, it has been used for sealing ships, furniture, and wooden beams in homes.Drying Time (dries slower): Pure Tung Oil will take longer to cure than Polymerized Linseed Oil since it's 100% pure and unprocessed by way of heat. It can take several days to feel dry to touch and up to a few weeks to fully cure and harden, depending on factors such as temperature and humidity. This slow drying time can be a disadvantage for projects that require a quick finish, however when it comes to natural alternatives for sealing wood surfaces, especially outdoors, Pure Tung Oil is unmatched.

Durability (more waterproof): Tung oil is highly renowned for its durability. It is exceptionally resistant to water, chemicals, and abrasion. This makes it an excellent choice for outdoor applications, such as outdoor furniture, grill accessories, wooden garden boxes, and other projects that will be exposed to outside elements. Tung oil can withstand the elements and maintain its protective qualities for extended periods. Of course tung oil is also suitable for high traffic indoor projects, such as dining tables and unfinished hardwood floors.

Application (easier to apply): In its raw form, its a heavy but smooth oil that can be easier to apply than Polymerized Linseed Oil. Generally application pads are recommended, but it can be applied with your hand.

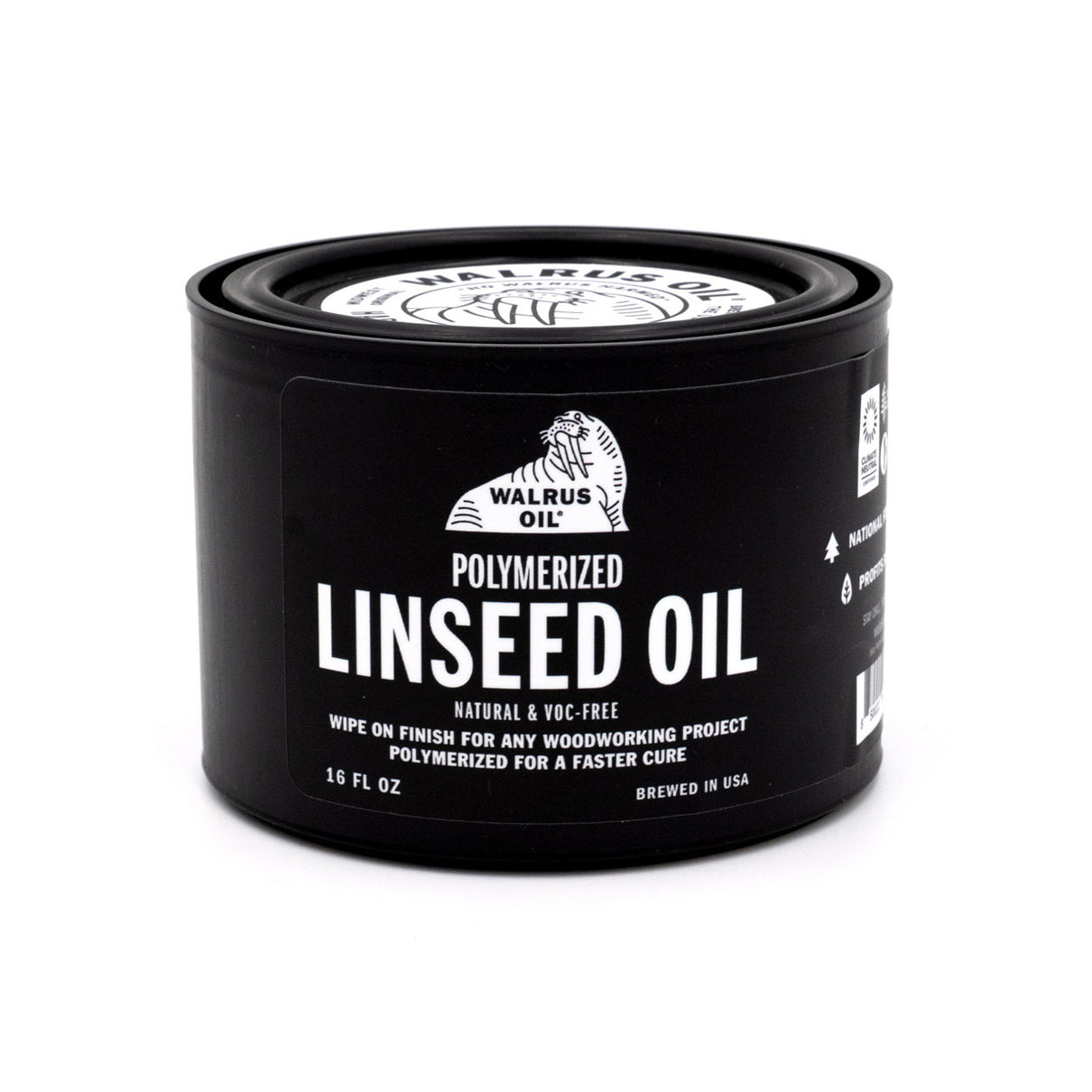

LINSEED OIL - The Fastest Curing Natural Finish

Brief Overview: Linseed Oil is extracted from the seeds of the flax plant. Flax has been cultivated for thousands of years and linseed oil has been used for various purposes, including wood finishes. Linseed oil contains a high percentage of linolenic acid and alpha-linolenic acid, which, like alpha-eleostearic acid in tung oil, polymerizes when it comes into contact with oxygen. This polymerization process is what causes the oil to harden and form a protective coating. Walrus Oil's Polymerized Linseed Oil has gone through a heating process to speed up the polymerization, so it will begin to cure even faster when applied to wood. While some companies use potentially harmful metals and dryers to polymerize their linseed oil, Walrus Oil does not and only processes our product through heat.Drying Time (dries faster): One of the most significant differences between tung oil and linseed oil is their drying time. Linseed oil, in contrast, dries relatively quickly, typically within 24 hours it's dry to touch. This faster drying time makes it a more suitable choice for projects where a speedy finish is desired. This also makes it easier to build coats of finish.

Durability (less waterproof): While linseed oil provides adequate protection for wood surfaces, it is generally not as resistant to moisture and UV exposure as tung oil. Linseed oil is better suited for indoor applications, such as furniture and cabinetry, where it can provide a protective finish without the need for extreme durability.

Application (harder to apply): In its raw form, due to it's pre-polymerization, its a very-thick oil and stickier than Pure Tung Oil. We recommend application pads or sandpaper when applying. Because of it's consistency, some may prefer to mix it with a natural solvent, although this is not required. It will require more buffing than Pure Tung Oil to apply and to remove any excess finish, though some may view this as a positive feature since more buffing contributes to more sheen.

Comments

M L Runge:

Thanks for the info. I am looking for a finish and it seems as though either might work for my needs. Can either take an over coat? The over coat in my case could be an epoxy, a urethane or shellac coating may be desired.

Dec 18, 2023

Jesse Glessner:

Are both of these oils usable as a food-grade finish for things like cutting boards, kitchen utensils, etc.?

Dec 18, 2023

Leave a comment